As we enter the third year of the war in 2025, Ukrainian allies and their advocates do so with a sense of uncertainty and disillusionment. Disillusionment not only from the failures of decisive action but also from the squandered opportunities to effectively support Ukraine in its brave struggle for freedom, sovereignty, and democratic ideals. What began as a conflict to resist invasion has evolved into a larger geopolitical reckoning, exposing the cracks in international unity and the dangers of inaction in the face of tyranny.

The missed opportunity to stand united against an increasingly belligerent authoritarian bloc led by Russia and supported by regimes such as Iran, North Korea, Belarus and China has allowed this “axis of tyrants” to expand its influence and cooperation. This coalition thrives on mutual defiance of international norms, exploiting divisions in the global community to bolster their respective ambitions. Among the most alarming developments is the systematic growth of Russia’s defence industry, which has become a cornerstone of its war effort and a key instrument for projecting power abroad, more specifically in Europe.

Despite severe sanctions and international condemnation, Russia’s defence sector has not only survived but adapted, leveraging new alliances, technological ingenuity, and clandestine networks. With the support of nations like Iran, which supplies drones and missile technology, and North Korea, which provides munitions, Russia has managed to sustain its military campaigns. China, though more cautious in its overt support, continues to provide critical economic lifelines and dual-use technologies that indirectly strengthen Russia’s military-industrial base.

This analysis will delve into the mechanisms driving the expansion of Russia’s defence industry amidst the war in Ukraine. It will examine the role of international partnerships, the strategic adaptations to sanctions, and the troubling implications of this unchecked growth for global security. By understanding how this authoritarian regime collaborates and innovates, we can better comprehend the stakes at hand and the urgent need for a more coordinated response to counter the ambitions of regimes that openly challenge the international order.

To understand the extent of the challenge Ukraine and Europe may face in the future is important to look at the current status of some of the military-related manufacturing sites. Of those identified 33 are potentially in the range of long-range weapons already or in close future at the disposal of the Armed Forces of Ukraine. Of these not all are actual factories producing war material, many are research centres, in particular in the Moscow area.

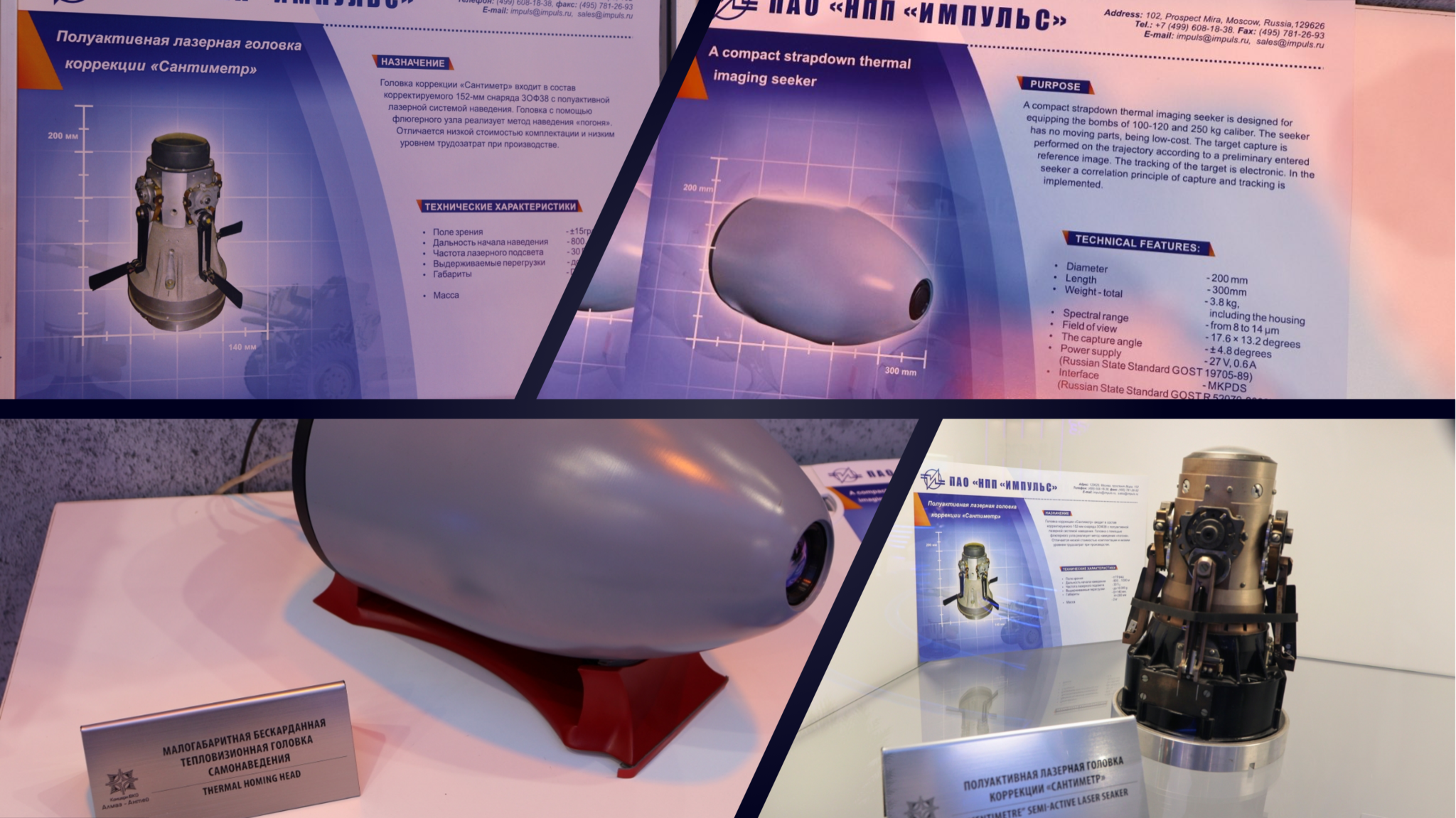

An example is the Join Stock Company (JSC) Scientific and Production Association Impulse, a famous and important design bureau responsible for the design of automated control systems for strategic missiles and cruise missiles like the Kh-29. This design enterprise has been active in developing several types of systems, from thermal homing heads to semi-active laser seekers.

Thermal imaging homing head key specifications:

- Field of View: ±15 degrees

- Guidance Activation Distance: 800–1,000 meters

- Laser Frequency: 30 Hz

- Can withstand up to 16,000 g of force

- Dimensions: 140 mm in diameter, 200 mm in height

- Weight: 2 kg

This compact thermal homing head is designed for use in missile systems, providing infrared-based guidance. By detecting heat signatures, it enables the missile to lock onto and track targets with high precision, even in challenging environmental conditions.

Always in Moscow another very important research complex which comprises the Red Banner of Labor, Test and Contract Enterprise, and the Federal Scientific and Technical Center Informkhimmash. The Red Banner of Labor SNPI SoyuzpromNIIproekt specializes in the design, development, and supervision of facilities handling explosive materials, hazardous substances, and high-risk industrial processes. Their expertise spans a broad spectrum of industries and activities, particularly focused on the safe management, production, and disposal of explosive and chemically hazardous materials. Their key area of expertise are stated below:

- Explosive Materials and Special-Purpose Facilities

The organization designs and oversees facilities for the research, production, testing, storage, transportation, and disposal of explosive materials. This includes:- Nitro compounds and gunpowder.

- Solid rocket fuels and composite materials.

- High explosives, pyrotechnics, ammunition, and military equipment.

- Industrial and Conversion Facilities

SoyuzpromNIIproekt also develops infrastructure for industrial and civilian applications, including:- Factories for producing industrial explosives and products containing them.

- Warehouses and transportation points for explosive materials.

- Chemical Production and Storage

The company is involved in the design of complex chemical production facilities, focusing on:- Organic synthesis, rubber processing, and polymer materials.

- Hazardous chemical processing, including nitric and sulfuric acid production.

- Destruction of chemical weapons in collaboration with research organizations.

- Technological and Hazardous Substances Management

Their expertise extends to managing flammable and chemically hazardous substances and designing facilities for storing materials like ammonium nitrate, aluminium powder, and petroleum products. - Gas Supply and Boiler Facilities

SoyuzpromNIIproekt provides services for gas supply systems, including:- LPG installations for industrial use.

- Gas control systems for boiler houses and power plants.

- Inspection and modernization of boiler facilities, including pressure vessels and pipelines.

- Safety and Emergency Systems

The organization develops regulatory, technical, and design documentation to ensure the safe operation of production facilities. This includes control systems, emergency protection measures, and waste disposal plants.

Red Banner of Labor SNPI SoyuzpromNIIproekt expertise focuses on explosives, chemical production, and safety systems ensuring that such operations are conducted safely and efficiently, minimizing risks to personnel and the environment.

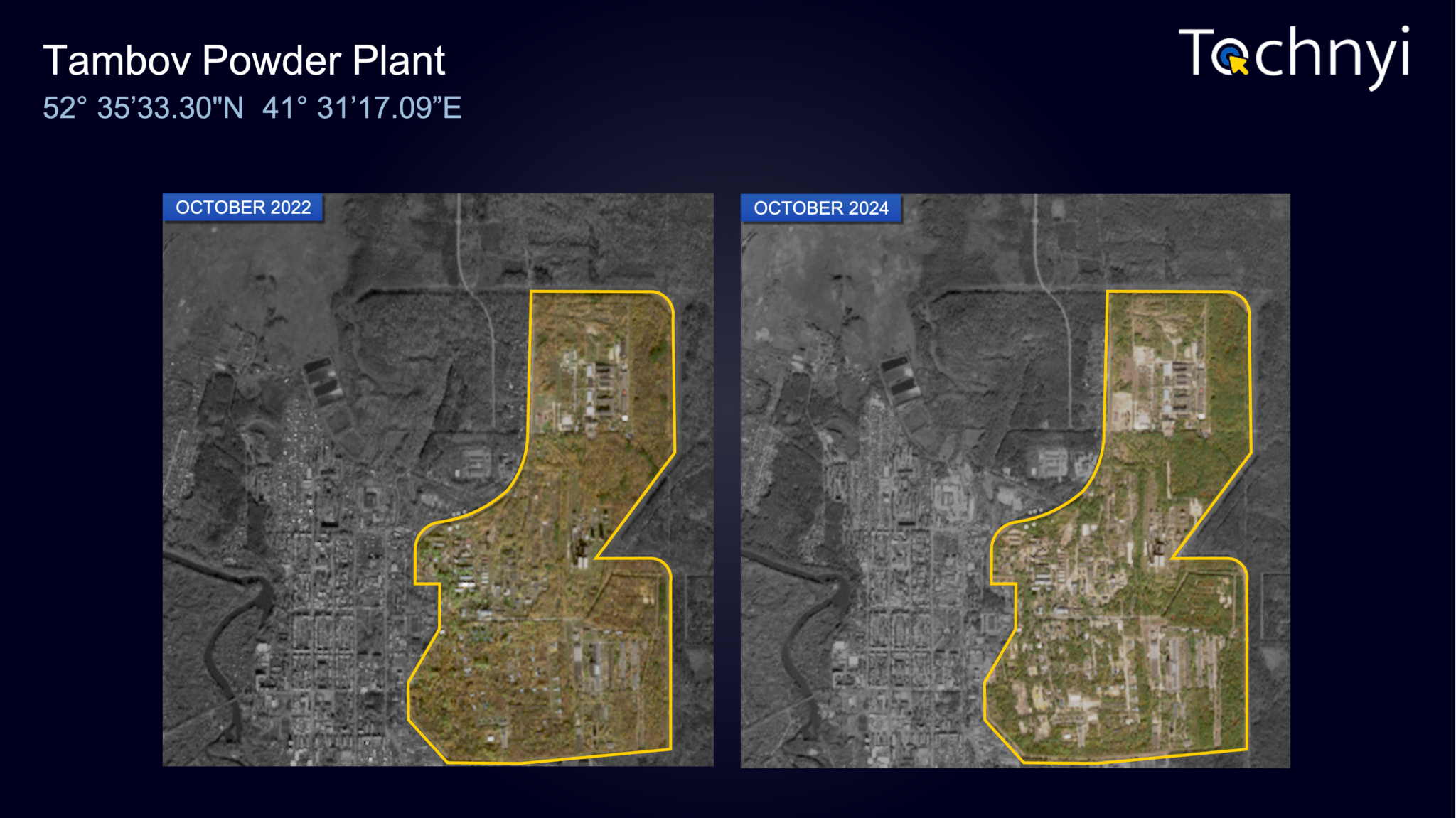

Within the range of the Storm Shadow/SCALP EG can be found a series of significant facilities that have experienced a certain level of expansion and improvement since the invasion initiated in 2022. One of these is the FSE Tambov Powder Plant, located in Kotovsk and established in 1915. It is a major Russian manufacturer of explosives, producing over 200 types of products, including gunpowder for small arms, artillery, and mortar ammunition, as well as civilian items such as varnishes, gloves, and toys. During World War II, the plant produced 90,000 tons of gunpowder and 40 million charges. Currently, 20% of its products are exported, and it reported a 34% increase in production in early 2022. The plant employs 1,800 people, with plans to expand the workforce to nearly 5,000 by 2025. In January 2023, the enterprise was transferred to the Rostec State Corporation, under the leadership of Oleg Syusyukin. It was recently visited by Dmitry Medvedev, who delivered a speech and expressed support for the ongoing expansion work at the plant.

Despite recent bankruptcy concerns, the plant has seen increasing expansion of both infrastructure and workforce, having hired 500 specialists by the end of 2022 and planning to recruit 3,000 additional employees by 2025 to support increased production demands. Gidroavtomatika is the contractor for the reconstruction. It is a Moscow-based construction firm with a 2018 revenue of 492.7 million rubles and a net profit of 4.8 million rubles. The ongoing modernization and integration into Rostec marks a new chapter for the Tambov Powder Plant, positioning it as a key player in both military and civilian production sectors.

The expansion of the site is clear and significant, as shown in satellite imagery obtained using Sentinel-2 at a 10-meter resolution. The area highlighted in red indicates where most of the site development has occurred. Several areas have been cleared of trees, and construction has been initiated. Most of the site is now scattered with buildings under construction, at various levels of completion. Although it is difficult to estimate the overall status from the resolution of the imagery, a video published by Russian media, a picture extracted from which is presented here, shows large concrete buildings now being erected.

Another chemical plant that experienced significant improvement and is even closer to the Ukrainian border and within the range of ATACMs is the Bryansk Chemical Plant, which was recently hit by a long-range attack on 13-01-2025. From satellite images (Airbus 2025), it is possible to see how much the landscape in the plant has changed. Several areas have been cleared from forest and new buildings are now being built.

Like many other chemical plants, this plant is key in producing propellant and explosives for the war effort. In particular, the Bryansk Chemical Plant has a crucial role in providing several materials for producing explosives and charges required for different artillery systems, from rocket artillery to gliding bombs. The plant is well-known for its production capacity across a wide range of systems, including BM-21 GRAD, BM-27 Uragan, Tornado-S and TOS-1 Buratino. It also operates several production lines for propellant charges used in artillery munitions and rocket-propelled grenades (RPGs).

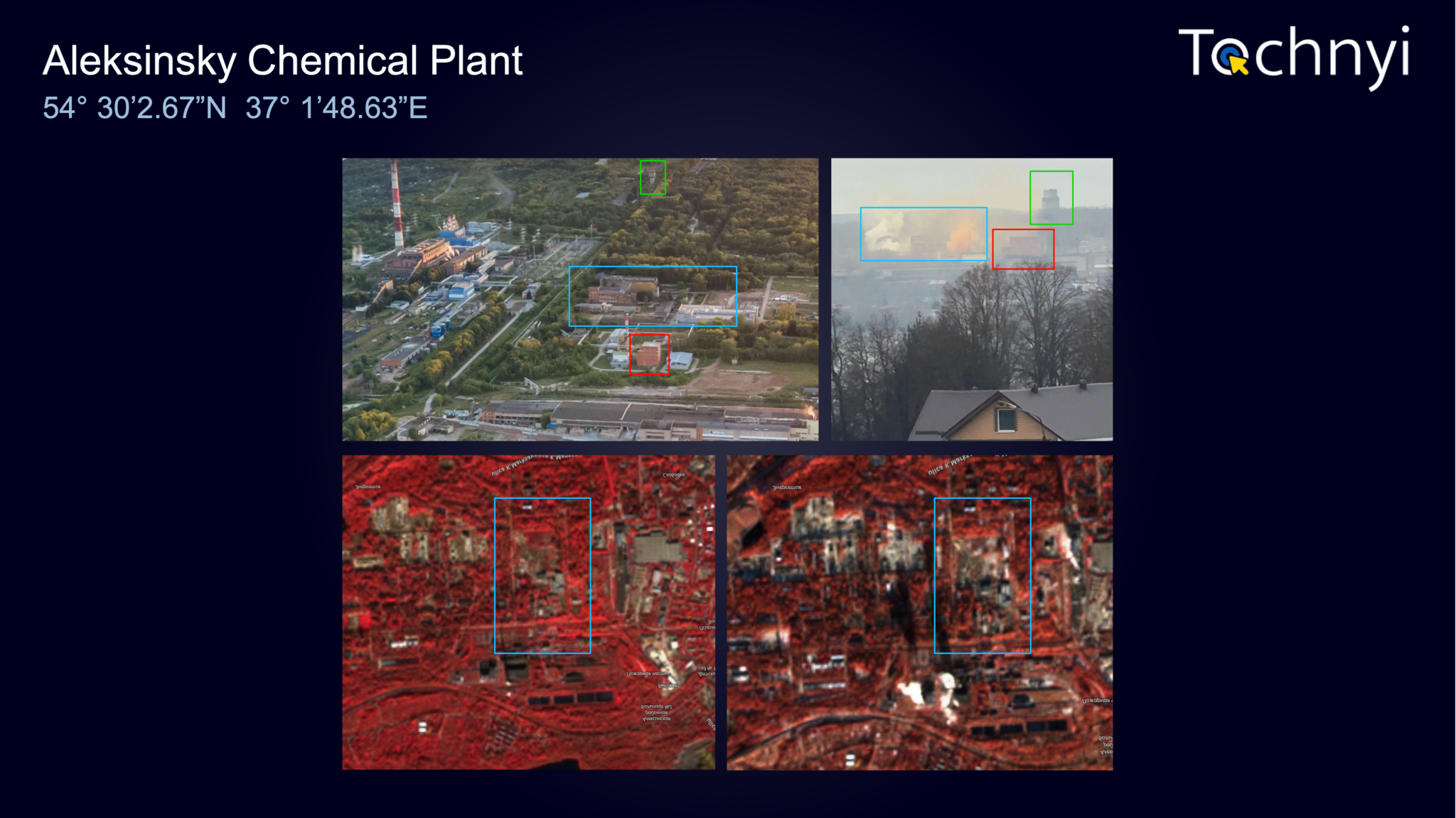

Other potential high-value targets in the range of Storm Shadow are the Tula Cartridge Plant and the FSE Aleksinsky Chemical Plant. The Aleksinsky Chemical Plant, located in the city of Aleksin in Russia’s Tula region, is a significant entity within the Russian military-industrial complex. Specialising in producing ammunition, gunpowder, and composite materials, the plant supplies essential components for the Russian Armed Forces. It operates under the umbrella of the state-owned corporation Rostec (UNITED24 Media).

In 2023, the United States imposed sanctions (for full sanction summary, see Table 1) on the Aleksinsky Chemical Plant due to its role in manufacturing military-grade materials for Russia’s defence industry. The European Union followed suit in February 2024, citing the plant’s contributions to the production of ammunition and explosives used by the Russian military. On November 9, 2024, the plant was targeted in a significant drone attack, reportedly carried out by Ukrainian forces. The attack involved at least 13 drones, leading to explosions and a substantial fire at the facility. The attack caused extensive damage, particularly to the gunpowder production workshop, and resulted in the evacuation of the plant’s staff (Obozrevatel).

Using open-source intelligence, including leaked videos, aerial photographs of the site, and Sentinel-2 optical imagery with a false-colour filter, it is possible to provide an initial estimate of the actual damage incurred. In the top left corner, an aerial image of the site is accompanied by a still, on the top right, from a video recorded by a Russian citizen on the morning after the strike. The area of major disruption can be easily identified using the building marked by the red square and the water tower indicated by the green box. The area affected by the explosion is located within the region highlighted by the violet box. Satellite imagery (Sentinel-2) taken before the strike on December 10, 2024, and after November 26, 2026, shows no significant damage at the site. Although the low resolution of the images makes it difficult to see detailed damage, most key structures appear unaffected. This is likely due to the relatively low payload capabilities of the long-range strike drones.

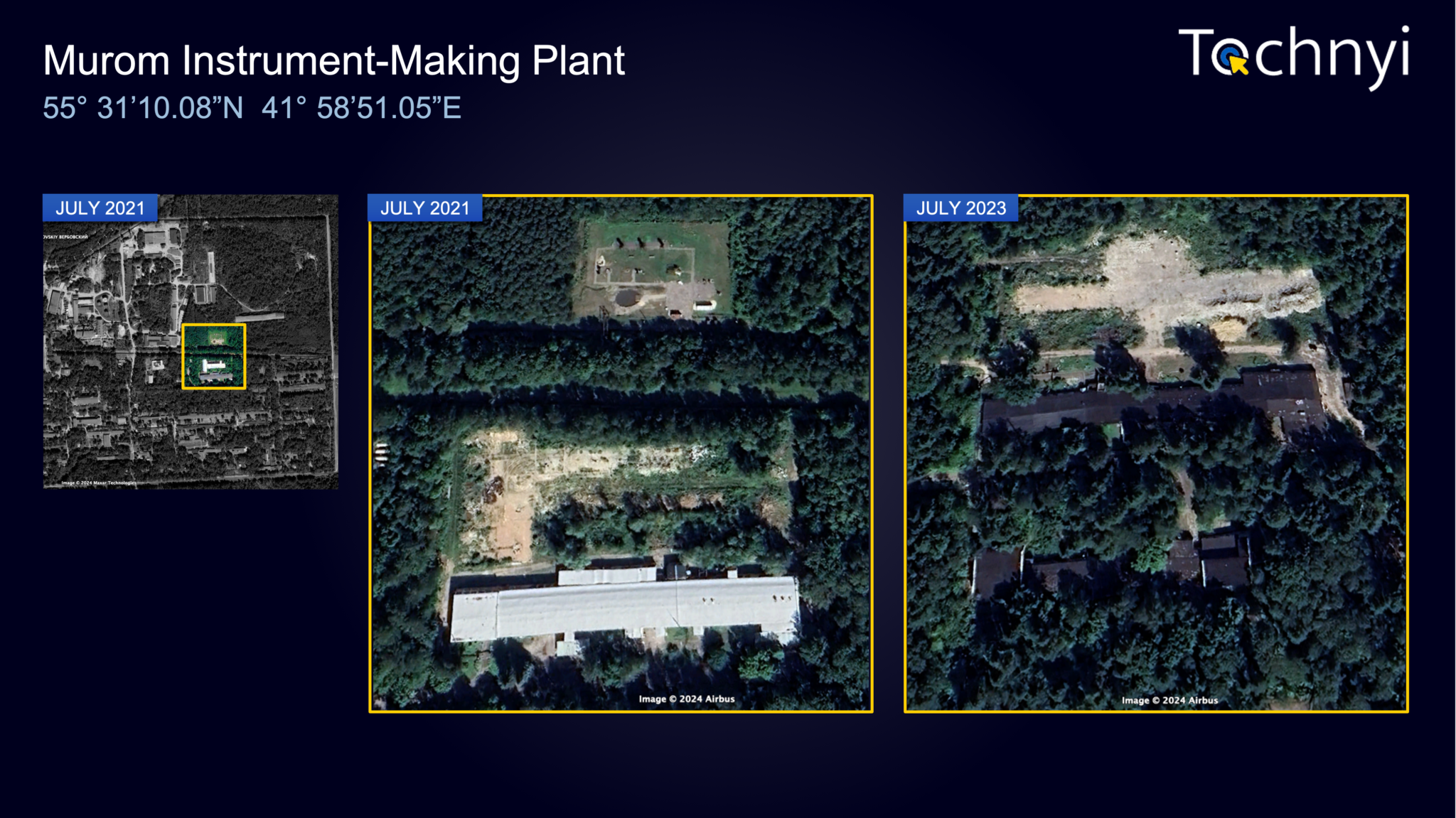

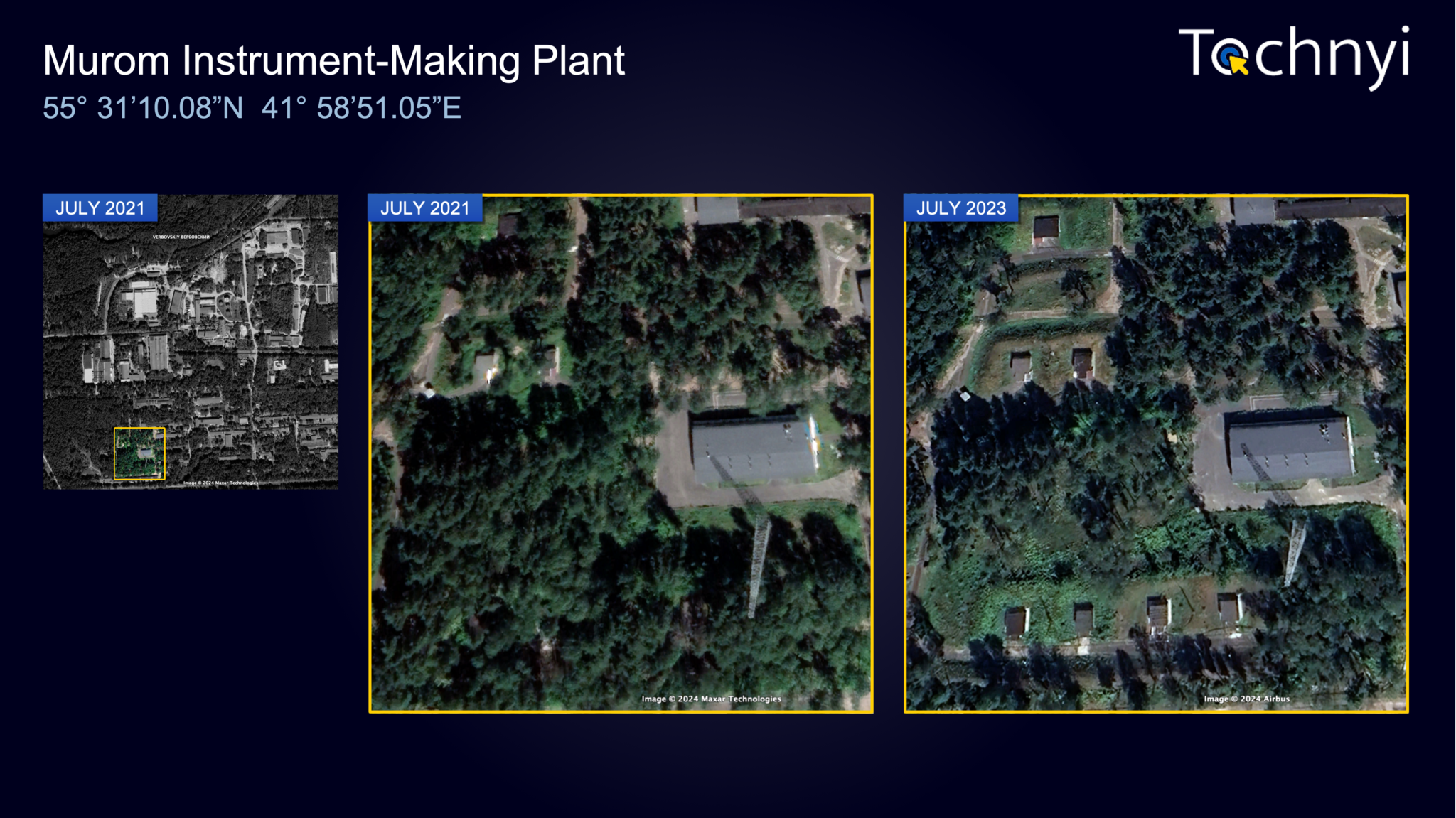

New developments have emerged at the Murom Instrument-Making Plant. Established in 1941, the Murom Instrument-Making Plant specialised in the production of ammunition initiation and ignition systems. The company serves as a key supplier to the Russian Armed Forces, the Ministry of Internal Affairs, the Federal Security Service, and other law enforcement agencies.

The plant specializes in producing devices that initiate and ignite ammunition, supporting operations across land, air, sea, and even space systems. Among its key products are pyrotechnic devices designed to activate rescue equipment in aviation, marine, and ground vehicles, as well as in space missions, including manned flights. Another important product line includes primers and igniters, which are essential components for various types of ammunition used in civilian, military, and sporting firearms.

The plant also leverages its expertise in dual-use technologies to develop initiation systems for fire extinguishing equipment, demonstrating its versatility in addressing both defence and civilian needs. The site shows several areas where new structures are planned, and some previously wooded areas have been cleared, indicating a clear intent to recommence the use of certain above-ground magazines, as illustrated in the figure below.

To further strengthen the relevance and critical expansion that the Russian defence industry is currently experiencing, it is worth examining the Biysk Oleum Plant and the Kazan Plant of Precision Engineering. Between May 2023 and September 2024, the Biysk Oleum Plant area has undergone significant transformations, primarily characterised by increased construction activity. The latest satellite image (Airbus 2025 high-resolution) reveals large-scale excavation and land clearing, particularly in the upper-left section. This suggests ongoing industrial or infrastructural expansion, with noticeable changes to the landscape.

New infrastructure has also emerged, with additional buildings and structures appearing in the northern section of the site. These developments indicate an expansion of facilities, possibly for manufacturing, storage, or administrative purposes. Alongside these new structures, some roads and pathways have been modified or expanded, likely to support increased activity in the area.

Another notable change is the alteration of the natural environment. The 2024 image (Airbus 2024 high-resolution) shows significant deforestation in multiple locations, possibly to make way for construction or other industrial operations. Additionally, a new large water body or industrial reservoir has appeared in the northern section, which could be linked to industrial processes or water management efforts. Overall, the comparison between the two images highlights rapid development and land use changes at the site. The increased infrastructure, land clearing, and new water features suggest a major expansion of industrial activities within the area.

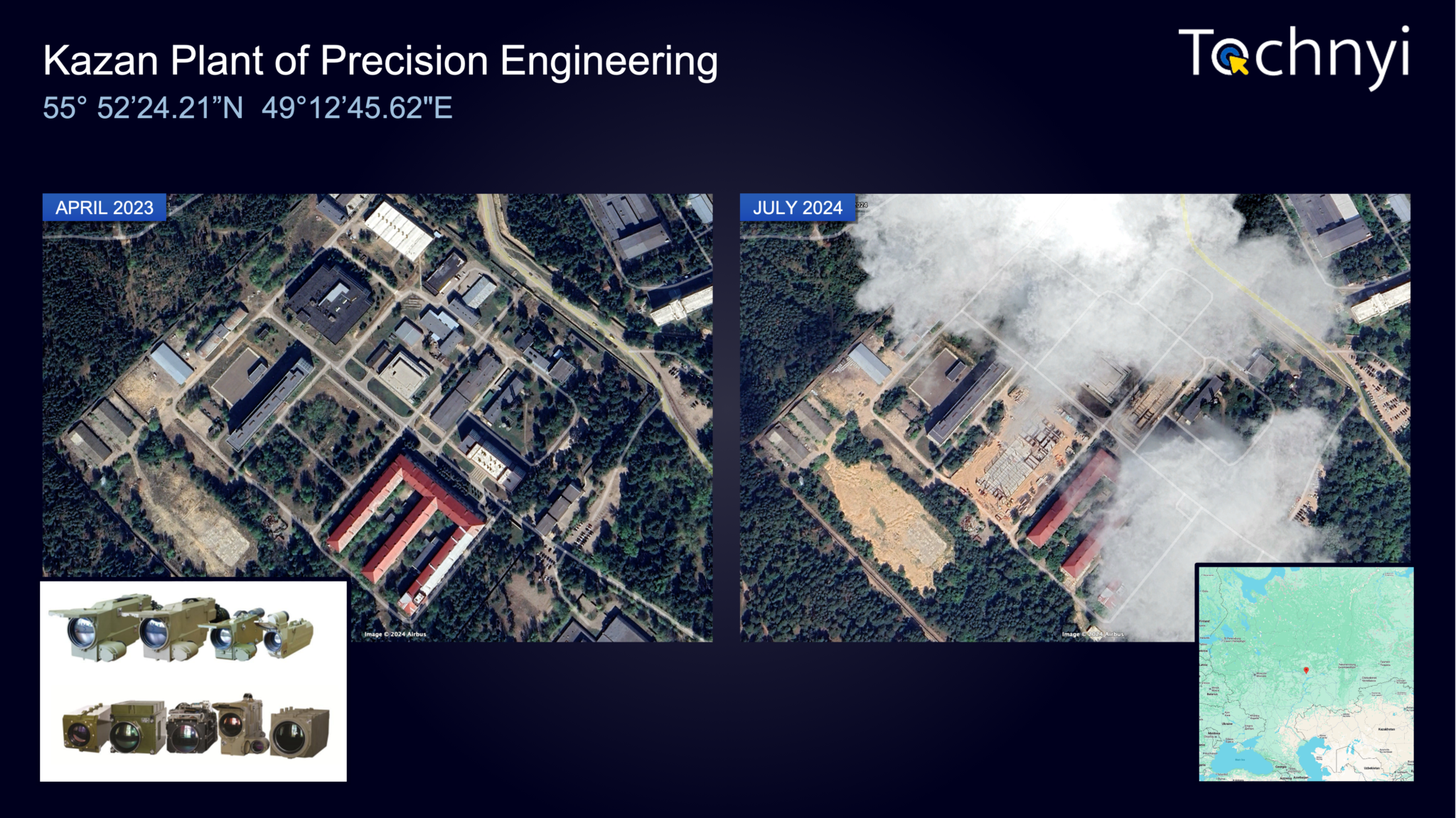

The Kazan Plant of Precision Engineering is a key industrial facility in Kazan, Tatarstan, specializing in the production of high-precision optical and electronic components. The factory is known for manufacturing thermal imaging devices, optical sights, and targeting systems used in military applications. These technologies are critical for armoured vehicles, drones, and advanced weapon systems, making the facility strategically important within Russia’s defence sector.

The satellite images of the Kazan Plant of Precision Engineering from April 2023 and July 2024 reveal significant changes to the site. In the 2023 image, the facility appears untouched, with multiple structures and organized industrial layouts in line with the previous years. However, by 2024, large portions of the site seem to have been cleared, with construction undergoing visibly in some areas. Additionally, some sections of the site appear to have been levelled, possibly for reconstruction or new development.

It is important to note that while the 2024 image (Airbus 2024) contains cloud cover, which obscures some details, the overall layout still indicates extensive alterations. The extent of the changes suggests that the facility may have undergone restructuring and expansion.

The detailed image of the Kazan Plant of Precision Engineering in July 2024 offers clearer insights into the ongoing changes at the site. The close-up view highlights active construction in a previously developed area, confirming that significant modifications are underway rather than mere destruction or abandonment. One of the most noticeable elements in the detailed image is a large-scale steel framework, indicating the construction of a new facility. The presence of construction materials, scaffolding, and heavy equipment suggests that this is an expansion rather than simple repairs. Compared to the 2023 image (Airbus 2023), where this area was occupied by existing buildings, the new structure appears to be in an early stage of development, with foundational work and vertical framing already in place. The surrounding landscape also reflects ongoing development. The ground appears to have been cleared and levelled, with visible storage of construction materials nearby. This suggests an organized effort to upgrade or expand the facility rather than a reactionary reconstruction. Additionally, the adjacent buildings remain intact, further supporting the idea that this is planned growth. Given the strategic nature of the Kazan Plant of Precision Engineering, this expansion could indicate increased production capacity. The continued investment in infrastructure suggests that the facility is either ramping up operations or modernizing its capabilities, to meet heightened defence demands present but also future.

Above all the sites investigated, here we presented only a few of the most relevant, it is worth giving some time to the Perm Powder Plant. The Perm Powder Plant is a significant Russian defence enterprise located in Perm, Russia. Established on June 5, 1992, the plant specialises in producing a wide range of military-grade propellants and explosives. Its product line includes charges for multiple launch rocket systems such as “Grad” and “Smerch,” air defence systems, engine charges for air-to-air missiles, and propulsion stages for sea-based cruise missiles, including those launched from submarines. Additionally, the plant manufactures components for anti-ship air-to-surface systems.

Throughout 2023 and 2024, the Perm Powder Plant faced multiple international sanctions due to its involvement in producing military equipment used in various conflicts. In December 2023, the United States Department of the Treasury added the plant to its sanctions list, targeting entities supporting the Russian military sector. Shortly thereafter, the European Union included the plant in its 12th package of sanctions, citing its role in manufacturing components for weapon systems employed in military operations. In February 2024, the United Kingdom also imposed sanctions on the plant, recognising its contribution to the Russian defence industry. The plant collaborated with other defence enterprises. For instance, in 2024, the plant, in partnership with the Federal Research and Production Center “Altai” dispatched a second batch of solid rocket fuel to Iran.

The first satellite imagery (Airbus 2024 high-resolution) comparison of the area surrounding the plant between May 2023 and June 2024 reveals significant changes in land use and infrastructure development. The most noticeable transformation is the extensive deforestation observed in the June 2024 image. Large portions of previously forested land have been cleared, indicating preparation for industrial or construction activities. This expansion is particularly evident around the manufacturing facility, suggesting ongoing or planned operational growth.

Additionally, infrastructure changes are visible, including the development of new roads and access routes. These newly constructed pathways connect the cleared areas, facilitating the movement of materials and personnel. The presence of additional roads suggests an organized expansion, potentially for industrial, logistical, or military purposes.

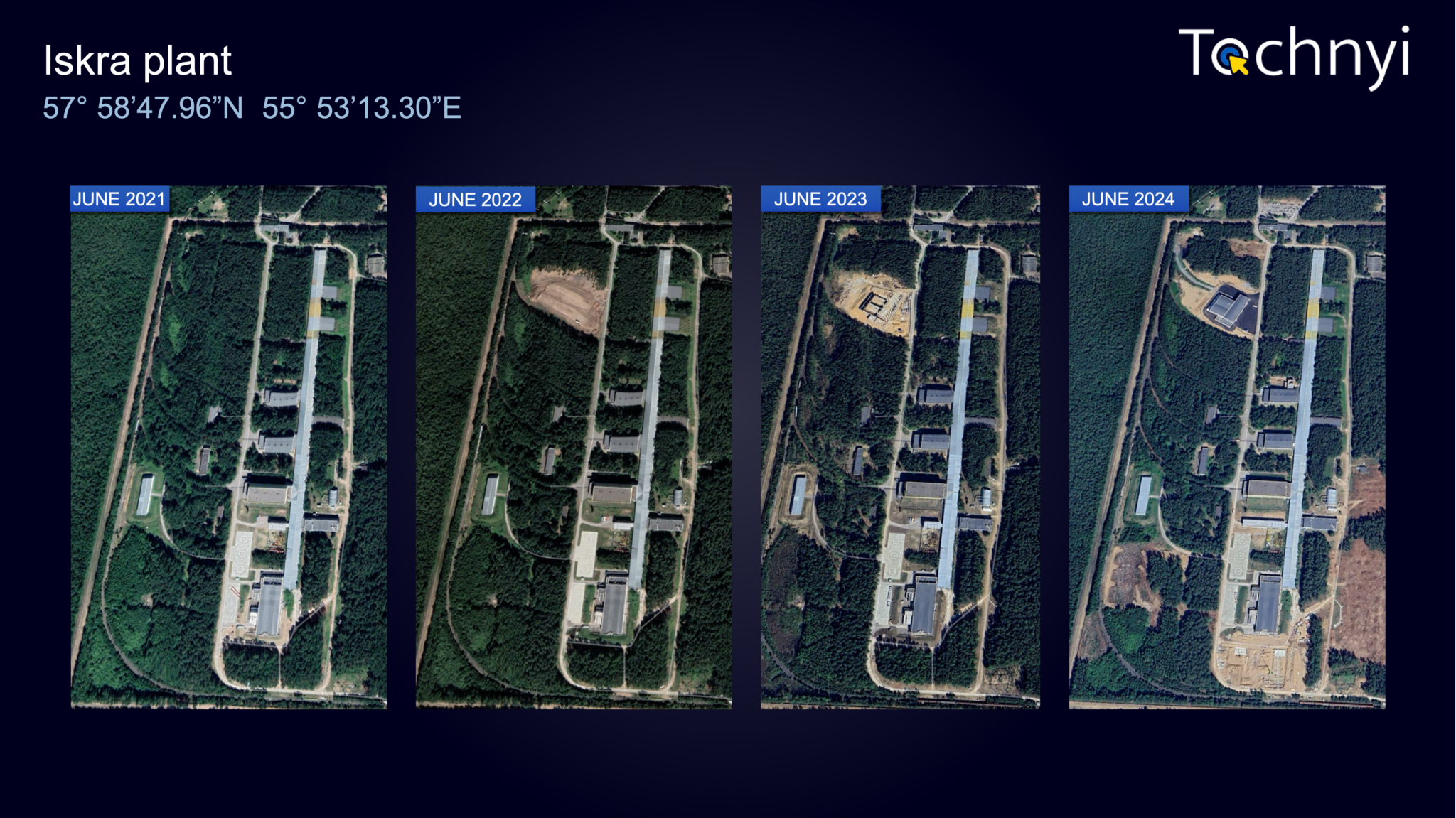

Among the areas where development has been most sustained, one is particularly noteworthy: the Scientific and Production Association Iskra plant, known for producing crucial components for ballistic and intercontinental missiles. This plant has a significant infrastructure located near the Perm Powder Plant. Despite attempts to present itself as involved in civilian work, Iskra plant is a leading manufacturer of solid-fuel rocket engines, liquid engines, and various other systems. The production process features a long assembly line, which is typical for large missile manufacturing. This assembly line is characterized by a continuous integration of missiles as they progress through the production stages.

This infrastructure, as illustrated in the image, has undergone significant changes since June 2022. A completely new building is expected to appear between June 2023 and June 2024. Additionally, further expansions are anticipated, as more forest clearing is observed in the lower part of the plant, with clear signs of deforestation indicating ongoing development. Despite the apparent shift to civil production of gas turbines, low demand and the current historical context clarify what the current production entails, which resembles the same scheme observed in other Russian industries, which on paper, are involved more in the civilian sector but in practice have deep ties with the defence sector.

The expansion and resilience of Russia’s military-industrial complex, despite extensive international sanctions and military pressure, highlight a troubling reality: inaction and disunity among democratic nations only serve to embolden authoritarian regimes. The war in Ukraine, now entering its third year, has become more than a fight for territorial sovereignty; it is a defining struggle for the principles of democracy, self-determination, and international security.

| Company Name | US Sanctioned | EU Sanctioned | Source |

| Production Association Impulse | Yes | Yes | OpenSanction |

| SoyuzpromNIIproekt | Yes | Yes | OpenSanction |

| Tambov Powder Plant | Yes | Yes | OpenSanction |

| Bryansk Chemical Plant | Yes | Yes | OpenSanction |

| Aleksinsky Chemical Plant | Yes | Yes | OpenSanction |

| Murom Instrument-Making Plant | Yes | Yes | OpenSanction |

| Biysk Oleum Plant | Unknown | Unknown | |

| Kazan Plant | Yes | No | OpenSanction |

| Perm Powder Plant | Yes | Yes | OpenSanction |

| Iskra Plant | Yes | Yes | OpenSanction |

Russia’s ability to circumvent sanctions, forge new alliances with states like Iran, North Korea, and China, and significantly expand its weapons production underscores the strategic miscalculations of those who believed economic pressure alone would cripple Moscow’s war machine. The modernization and expansion of key military production facilities from the Tambov Powder Zavod and Bryansk Chemical Plant to the Perm Powder Plant and Iskra plant and many others left out in this report illustrate the Kremlin’s long-term commitment to sustaining its military operations and advancing its strategic ambitions.

The documented improvements in Russia’s defence sector serve as a stark warning to Ukraine and its allies: failure to decisively counter these developments will not only affect the war in Ukraine but also increase the threat to Europe’s stability. Ukraine’s recent long-range strikes on military infrastructure have demonstrated the effectiveness of targeting these sites, yet without consistent and enhanced support from Western allies, these efforts remain limited in their long-term impact. Precision strikes, combined with sustained economic pressure and strategic military aid, are essential in degrading Russia’s capacity to wage war.

If the world fails to confront this growing threat with the urgency it demands, the consequences will extend far beyond Ukraine’s borders. The lessons of history remind us that unchecked aggression and authoritarian expansionism only grow more dangerous when met with hesitation and half-measures. The continued resistance against Russia is not just about supporting Ukraine it is about defending the fundamental values that underpin the international order. The cost of inaction is not just measured in the lives lost on the battlefield but in the erosion of global security, the empowerment of authoritarian regimes, and the precedent set for future conflicts.

The time for decisive and unified action is now. Ukraine’s struggle is a battle for the free world, and its victory or failure will shape the geopolitical landscape for decades to come. The question is no longer whether we can afford to act, but whether we can afford not to.